How are Japanese woodblock prints made

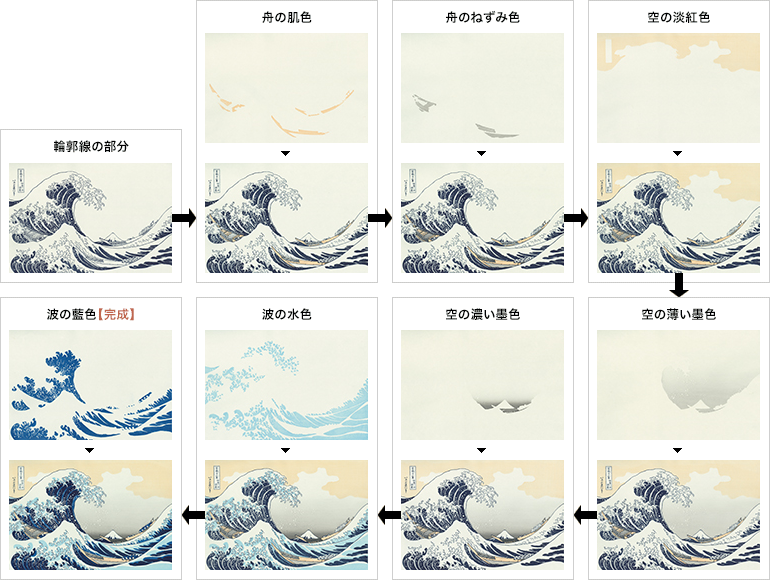

Blocks are carved one by one, each colour a new woodblock. The blocks are then taken to the printer, who arranges the blocks in sequential order and prints them on Japanese rice paper (which is made from mulberry bark) using water colours.

How is a woodblock made

The wooden block is usually made from pear wood, which is sawn along the grain and planed smooth. The block is then seasoned to reduce the moisture content in the wood, which prevents warping and cracking. The size of the woodblock is determined by the image, but is ultimately limited by the size of the printing press.

How does woodblock printing process work

In woodblock printing, an image is carved in reverse on a piece of wood, leaving the image's outline on the wood, and the block is then inked and printed on a substance like paper or fabric. It's a time-consuming process, especially if you want to add more than one color during the printing process.

What is the material used in Japanese woodblock printing

The woodblock is made from the wild mountain cherry tree which has very hard-grain. It is the best material for the woodcut printing which is often used for mass production. Mineral and botanical pigments are mainly used. In addition to black (sumi), red, blue and yellow are the three primary colors.

How do you make woodblock prints

Creating, Cutting and Printing Your Own WoodblockStep 1: Getting Hold of the Basic Tools.Step 2: Draw Your Image and Copy It Onto Your Block.Step 3: Cut Your Block.Step 4: Ink and Print With Your Block.Step 5: Fix, Re-cut and Re-ink.61 Comments.

Why are woodblock prints so expensive

Woodblock Printing Artists

Exceptional examples by master printmakers like Hiroshige, Hokusai, and Kitagawa Utamaro, which tend to make infrequent appearances on the open market, fetch impressive prices due to their age and rarity.

How were printing blocks made

Printing blocks are normally made of wood, metal or a combination (such as having a wooden base with metal nails or bands hammered into its surface). A design is drawn onto the block surface. It is either engraved (sunk design) or the area around the design is carved away (raised design).

How is block printing made

Block printing is the relief process of printing onto fabric or paper using a hand-cut block, made of wood or linoleum. After the block has been carved, ink is applied, and then it is printed. Hence, the name block printing. It's a technique that has been around for more than two thousand years.

What are the materials used in woodblock

Woodblock Materials, Tools and Techniques

The wood chosen for woodblocks was sakura (cherry wood), a fine-textured wood with a straight grain. This is hard enough for intricate carving in high relief and will survive through the production of many copies of the print.

What is woodblock art technique

Each page or image is created by carving a wooden block to leave only some areas and lines at the original level; it is these that are inked and show in the print, in a relief printing process. Carving the blocks is skilled and laborious work, but a large number of impressions can then be printed.

How can I tell if my woodblock is real

Compare the key block lines (the lines that are almost always black and represent the basic drawing of the design) with a good photograph or illustration of a known original. Look at all the lines (including signatures and inscriptions) and compare how the lines or strokes end or vary in thickness, direction, or angle.

Do woodblock prints fade

Light represents a great risk to many artworks, including Japanese woodblock prints from the 18th and 19th centuries. This is because they were often made using plant-based dyes, which can fade when exposed to light. Many Japanese prints have faded dramatically since they were made.

How blocks are prepared for block printing

These blocks are usually made on teak or seesham wood. Artisans make sure that the wood is seasoned and then carve the motifs on it. The design are first printed on paper and stuck on the block of wood. Artisan, then start carving the wood with steel chisels, of different widths and cutting surface.

How is traditional block printing done

They lay the fabric across a long table and draw a chalk reference line. They dip the block into the dye and press it firmly onto the fabric. This process is repeated over and over again, with only the steadiest hands, until the pattern has completely covered the length of the fabric.

What are the techniques of block printing

Let's have a more detailed look at the technical Block Printing Process.Step 1: Block Carving. It is the Chhipa Community (Rajasthan) that possesses a majority of block carvers, dyers and printers in India.Step 2: Application of Dye.Step 3: Treatment of Fabric.Step 4: Printing.

What is the process of block printing

The block printing process involves engraving a design on the material, known as the block, inking the design, and then using the block as a stamp on the fabric. The resulting design will be a mirror image of the one on the block. The block may be a piece of wood, plastic, or any other suitable material.

How are block prints made

Block printing is the relief process of printing onto fabric or paper using a hand-cut block, made of wood or linoleum. After the block has been carved, ink is applied, and then it is printed. Hence, the name block printing. It's a technique that has been around for more than two thousand years.

What are the methods of block printing

There are two main types of block printing methods used for Passion Lilie's fabrics: pigment dyeing, primarily used on a white based fabric as the dye sits on top of the fabric, and reactive dyeing, used with a dark base fabric as the dye reacts with the fabric and changes the base color of the fabric.

How block printing is done step by step

Let's have a more detailed look at the technical Block Printing Process.Step 1: Block Carving. It is the Chhipa Community (Rajasthan) that possesses a majority of block carvers, dyers and printers in India.Step 2: Application of Dye.Step 3: Treatment of Fabric.Step 4: Printing.

What are 3 materials used for block printing

Tools and raw materials required for:•Wooden Tray with a Bamboo Lattice Bed Cover: Wooden Tray with a Bamboo Lattice bed cover is used for spreading of the color evenly.Brushes: Brushes are used to clean the surface for better printing.Scale: Scale is used for marking the areas to be printed.

What are the methods used in block printing

Block, or relief, printing includes linocuts, lino prints, woodblock prints, rubber stamping – pretty much any method where you carve into a material (a block, plate, etc.) and print an impression of the carved surface with ink.

What technique is used in block printing

The block printing process involves engraving a design on the material, known as the block, inking the design, and then using the block as a stamp on the fabric. The resulting design will be a mirror image of the one on the block. The block may be a piece of wood, plastic, or any other suitable material.

How is a printing block made

Block printing is the relief process of printing onto fabric or paper using a hand-cut block, made of wood or linoleum. After the block has been carved, ink is applied, and then it is printed. Hence, the name block printing. It's a technique that has been around for more than two thousand years.