Is 3D printing considered a digital technology

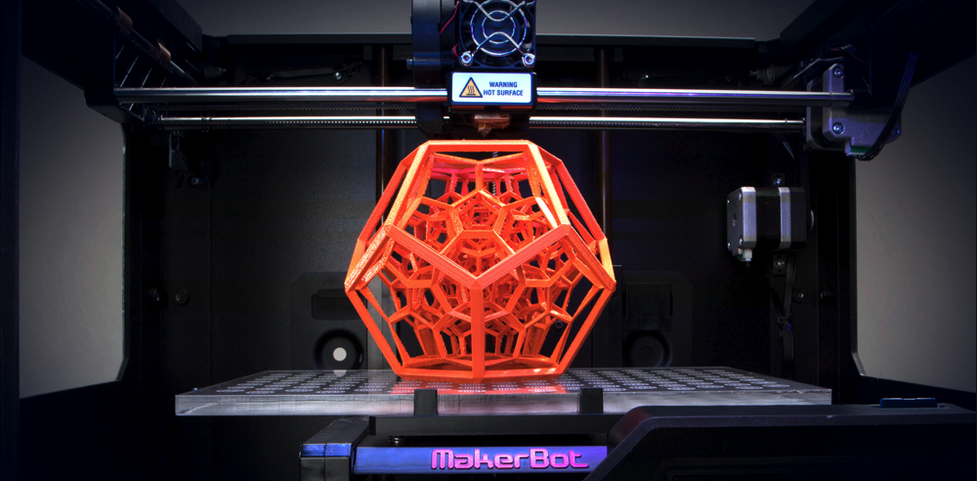

Digital fabrication technology, also referred to as 3D printing or additive manufacturing, creates physical objects from a geometrical representation by successive addition of materials. 3D printing technology is a fast-emerging technology. Nowadays, 3D Printing is widely used in the world.

What type of manufacturing is 3D printing

additive manufacturing

3D printing, also known as additive manufacturing, is a method of creating a three dimensional object layer-by-layer using a computer created design. 3D printing is an additive process whereby layers of material are built up to create a 3D part.

Is 3D printing considered manufacturing

3D printing, also known as additive manufacturing, has come a long way since it was first developed in the 1980s. While 3D printing originated as a tool for rapid prototyping, it has now evolved to cover a number of different technologies.

What is digital manufacturing 3D printing

3D printing, also known as additive manufacturing, is a process by which three dimensional solid objects are created by depositing materials in layers based on a digital model. All 3D printing processes require software, hardware, and materials to work together.

Is 3D printing smart manufacturing

3D printing, also known as additive manufacturing, is a rapidly growing technology that has changed the way companies design, prototype and produce products. Smart factories primarily use 3D printing to manufacture complex parts and components quickly and precisely.

What counts as digital technology

Digital technologies are electronic tools, devices, systems, and resources which generate, store or process data. Digital tools include social media, mobile phones, online games, and multimedia.

What is the difference between 3D printing and manufacturing

In summary, the main difference between 3D printing and additive manufacturing is that 3D printing specifically involvesthe creation of objects by adding layersof material. Yet additive manufacturinginvolves the creation of objects by adding material, which may or may not come in layers.

Is printing a manufacturing industry

To treat printing as a stand-alone product, service, or process is impossible. It is a manufacturing industry in the strictest sense, but it is also a service industry.

What is meant by digital manufacturing

Digital manufacturing is an integrated approach to manufacturing that uses computer technologies to improve manufacturing operations.

Is additive manufacturing smart manufacturing

Additive manufacturing (AM) is a smart manufacturing technique that fabricates components directly from 3-D models by selectively joining materials.

What are 5 example of digital technology

There are many more such examples such as Cars, 3D printing, ATM Machines, Robotics, Drones and Missiles, Banking and Finance, Gadgets, Social Media, Digital Music, etc.

What are 3 examples of digital technology

Simple Examples of Digital TechnologyVideo technologies for working from home.GPS, What3Words and Location.5G and Virtual Reality.Smart homes.Cloud and SaaS.Artificial Intelligence (AI)Deep fake and AI.Bitcoin and blockchain.

Will 3D printing replace manufacturing

So, will 3D Printing Replace Traditional Manufacturing Well, considering the comparison we have done above, it would take decades for 3D printing to replace traditional manufacturing. In the near future; however, we can say that 3D printing could modify or improve some processes in the industry.

What are 3 examples of manufacturing industries

Examples of manufacturing include automotive companies, bakeries, shoemakers and tailors, as they all create products, rather than providing services.

What comes under digital manufacturing

Digital manufacturing is the use of an integrated, computer-based system comprised of simulation, 3D visualization, analytics and collaboration tools to create product and manufacturing process definitions simultaneously.

What technology is used in digital manufacturing

However, every digital manufacturing process involves the use of computerized numerical controlled machines (CNC). This technology is crucial in digital manufacturing as it not only enables mass production and flexibility, but it also provides a link between a CAD model and production.

Is additive manufacturing digital

Additive manufacturing is part of the digital movement and therefore a key element of the production of tomorrow. With our technology, we help organizations to imagine and develop innovations beyond existing boundaries.

What are 4 examples of digital systems

Digital systems are all around us in the form of computers, smartphones, scanners, cash registers and digital ticket readers. They are used by the local vet and by community firefighters.

What are the 4 types of manufacturing

What are the 4 types of manufacturing processCasting and molding.Machining.Joining.Shearing and forming.

What are 5 examples of manufacture

For example, all of these exist within the manufacturing industry:Food manufacturing.Textile product mills.Apparel manufacturing.Wood product manufacturing.Chemical manufacturing.Computer and electronics product manufacturing.

What do you mean by digital manufacturing

Digital manufacturing is the use of an integrated, computer-based system comprised of simulation, 3D visualization, analytics and collaboration tools to create product and manufacturing process definitions simultaneously.

What is also called digital manufacturing

Digital Manufacturing and its importance

Manufacturing is the process of producing goods to sell to customers. Digital manufacturing is a part of smart manufacturing, which is the fusion of virtual and physical worlds through cyber-physical systems (CPS). It can also be called industry 4.0 or smart factory.

What does digital manufacturing include

The Three Aspects of Digital Manufacturing

It can be broken down into three main areas; product life cycle, smart factory, and value chain management.

What are the 5 manufacturing process types

Five Types Of Manufacturing Processes:Repetitive Manufacturing. Basic manufacturing that creates the same product on an assembly line is engaged in the repetitive manufacturing process.Discrete Manufacturing.Job Shop Manufacturing.Continuous Process Manufacturing.Batch Process Manufacturing.

What are the three types of manufacturing

Three common types of manufacturing production processes are: make to stock (MTS), make to order (MTO), and make to assemble (MTA). Such strategies have advantages and disadvantages in labor costs, inventory control, overhead, customization, and the speed of production and filling orders.