What are the pros and cons of flexographic printing

Fast-Drying and Quick Process

Flexo printing also has the advantage of producing a finished product at the end of the process without having to wait for inks to dry. On the downside, flexographic printing isn't very advanced. It can't produce complicated and extensive artwork like other digital printing techniques.

What are the advantages of flexo printing

6 advantages of flexographic printing for the hygienic sectorVersatility.Wide variety of inks.Performance.High quality image reproduction.Low production cost.Eco-sustainability.

What are the advantages of flexography over gravure

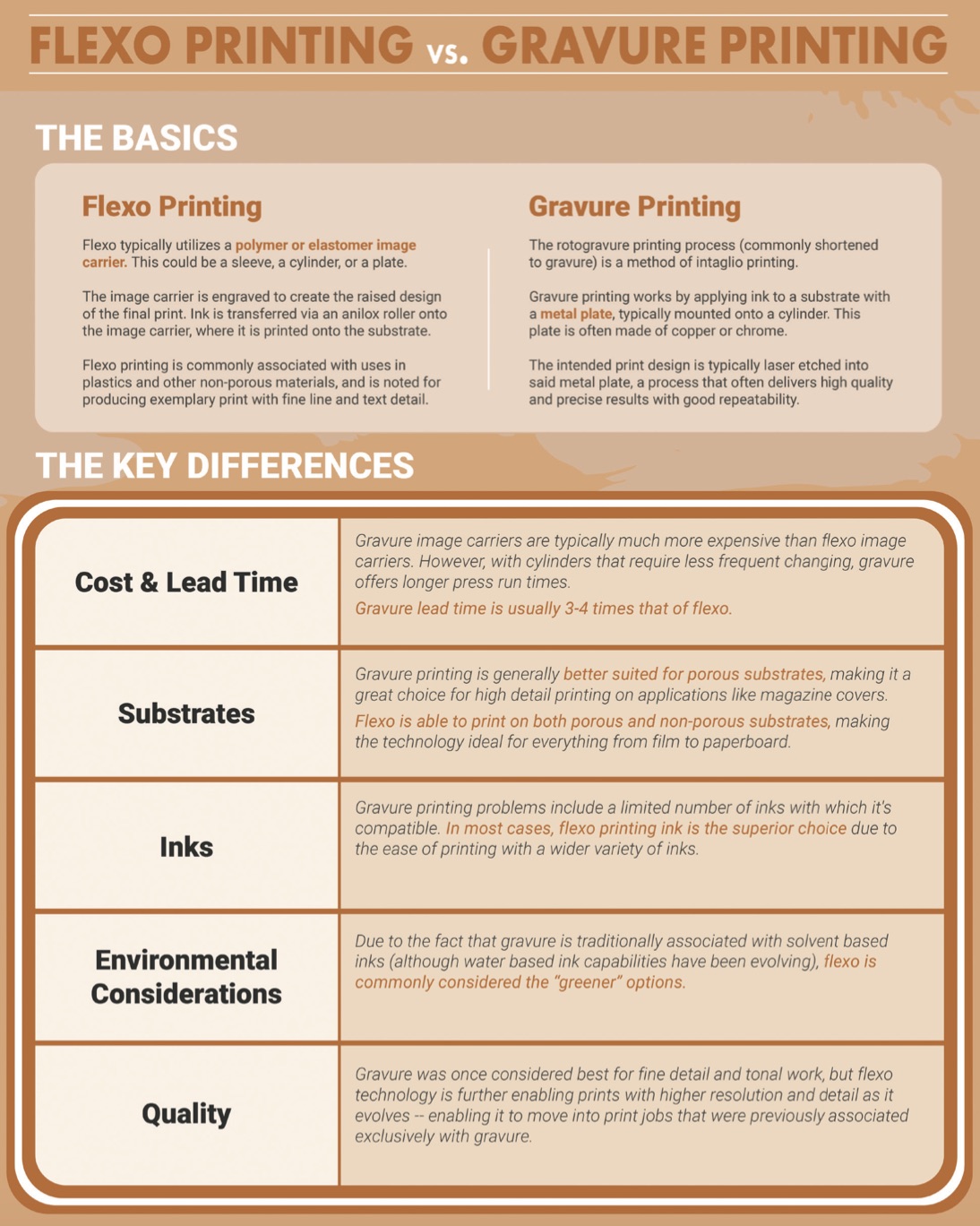

Gravure printing problems include a limited number of inks with which it's compatible. In most cases, flexo printing ink is the superior choice due to the ease of printing with a wider variety of inks. Gravure requires much more ink per print, which can drive up the cost of printing.

What is the main difference between gravure and flexo printing

Flexo — Flexo printing has a much shorter lead time than gravure, which requires less frequent changing of the cylinder. The print run time for gravure is longer as well. Flexo is able to print on both porous and non-porous substrates, making the technology ideal for everything from film to paperboard.

What are the cons of flexo printing

Disadvantages of flexographic printing are concentrated in the areas of printing plate production and, in some cases, limited print quality. For example, the production and assembly of the printing plates is comparatively extensive and time-consuming, which is (too) cost-intensive, especially for short runs.

What are the disadvantages of flexographic printing

On the downside, flexographic printing is not very advanced. It cannot produce complicated and extensive artwork as compared to that produced by rotogravure printing. The colors in the final product of flexographic printing are neither as bold nor as crisp as they are in rotogravure printing.

What is the difference between flexo and digital printing

Digital printing is a plate-free printing technology that requires virtually no setup time. The elimination of setup and plate costs makes digital printing competitive for small-to-midsized label orders — but its slower production speed makes flexo the better choice for longer runs.

What are 3 disadvantages of a printer

DisadvantagesThe printing basically depends on character codes, which makes elaborate layouts unavailable.Limits the fonts and font sizes.An internal data processing of the printer may take a long time when processing a large amount of data.

What are the 5 disadvantages of digital printing

Cons of digital printing.the range of printable fabrics is more limited than with screen printing.the print is not so durable.the colour white cannot usually be reproduced within the print.due to fixed pricing, bulk printing does not offer scaled cost reductions.

What is the difference between litho and flexo printing

Generally speaking, litho printing is better for full-color printing with detailed patterns and can accommodate more finish options. Flexo printing is a more direct process that can provide faster printing times and lower costs, but without the detailed colors and image quality of litho printing.

What are 2 disadvantages of a printer

DisadvantagesThe printing basically depends on character codes, which makes elaborate layouts unavailable.Limits the fonts and font sizes.An internal data processing of the printer may take a long time when processing a large amount of data.

What are advantages and disadvantages of printers

Solid Ink Printers

The print drum presses the ink onto the paper (or print medium). PROs: Low long term cost, print quality, ease of use, eco-friendly. CONs: Slow warm-up, high power consumption, high initial cost.

What are the pros and cons of digital printing

Digital Printing Benefits and LimitationsIncredible Quality.Low costs at low volumes compared to traditional printing.Multiple Versions or Variable Data flexibility.Short Lead Times.Prototyping or Constantly Revising Artwork.Large Volumes Cost More.Color / Ink Limitations.

What are the pros and cons of using digital technology in printing

You can achieve longer print runs with digital, but printing a higher volume this way can be more expensive than with offset. Toner-based colors can have limitations. While color options continue to evolve with digital printing, most digital printers are not able to print a Pantone Matching System color.

What are the pros and cons of all in one printers

Pros: Improves Document Management.Pros: Better Document Control.Pros: Reduce Costs.Pros: Reduce Learning Curve.Pros: Space Savings.Cons: Increase Waiting Time.Cons: Expensive Downtime.Cons: Fewer Features Compared to Specialized Devices.

What are three disadvantages of printing

Disadvantages of Print MaterialsNo interactions. Print materials do not generally provide built-in interactions.No audio/visual elements. Print materials are static and are not appropriate for teaching languages and visual concepts.Require reading skills.Time delay.

What are the 5 advantages of digital printing

Advantages of digital printingFull color. Various design possibilities with full color and gradation print without the limitation of colors.Quick delivery.Color matching time is reduced.Low cost.Simple.Small volume production.High added value.Environmentally friendly.

What are the pros and cons of thermal printer

A Quick Comparison Table of Thermal Printer Advantages and Disadvantages

| Thermal Printer Advantages | Thermal Printer Disadvantages |

|---|---|

| – Fast printing speeds | – Restricted color options |

| – Consistent code results | – Codes are not designed to last long-term |

| – Few moving parts | – High consumable costs |

What are the pros and cons of 3D printing

Pros: allows you to make new shapes, it's eco-friendly and it saves time. Cons: doesn't always work well for large projects, appropriate materials aren't always available and it has regulatory challenges.

What are the PROs and CONs of using digital technology in printing

You can achieve longer print runs with digital, but printing a higher volume this way can be more expensive than with offset. Toner-based colors can have limitations. While color options continue to evolve with digital printing, most digital printers are not able to print a Pantone Matching System color.

What are the disadvantages of thermal printing

The biggest disadvantages of thermal printers are that they tend to be more expensive than regular printers, you need to purchase thermal paper, they have color limitations, thermal labels fade overtime, and print heads can get damaged by heat and they are expensive to replace.

What is the cons of 3D printing

Even though the technology can produce low to medium volume production levels, the cycle time is not as fast as traditional additive processes. Size – Industrial 3D printers need larger print chambers. Although some specialized 3D printers manufacture large products, much of the technology is limited to smaller builds.

What are the pros and cons of 3D food printing

The ability of consumers to personalize what they eat and how their foods look is an exemplary advantage of 3D food printing, while some current disadvantages include the cost, availability of “food inks”, and safety concerns.

What are 4 disadvantages of thermal expansion

Disadvantages of thermal expansion of solids

(1) Changing of shape and dimensions of objects such as doors. (2) Wall collapsing due to bulging. (3) Cracking of glass tumbler due to heating. (4) Bursting of metal pipes carrying hot water or steam are some of the disadvantages of thermal expansion of matter.

What are the disadvantages of 3D food printing

3D-printed foods usually have a limited shelf-life due to structural changes that can occur over time as well as the potential, in some instances, for microbial growth. To reduce the food safety risks, the printers need to be hygienically designed with food grade material so that they can be cleaned thoroughly.