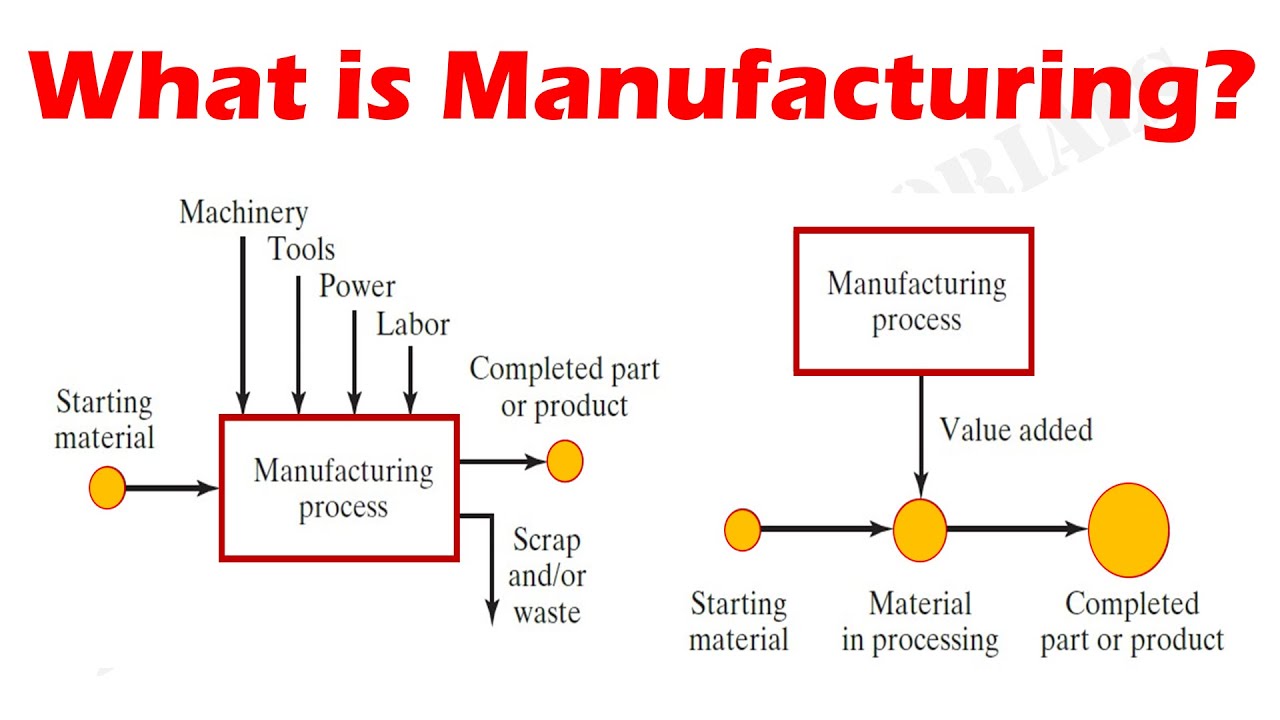

What is included in the manufacturing process

Therefore, manufacturing operations involves all the processes—including inventory management, materials requirement planning (MRP), supply chain management, sales management, production cost, and quality control—needed in order to produce goods for consumers and earn profit.

What are the 4 types of manufacturing processes

What are the 4 types of manufacturing processCasting and molding.Machining.Joining.Shearing and forming.

What are the 5 manufacturing process types

Five Types Of Manufacturing Processes:Repetitive Manufacturing. Basic manufacturing that creates the same product on an assembly line is engaged in the repetitive manufacturing process.Discrete Manufacturing.Job Shop Manufacturing.Continuous Process Manufacturing.Batch Process Manufacturing.

What is an example of process manufacturing

For example, a bottle of juice is a discrete item, but juice is process manufactured. The plastic used in injection moulding is process manufactured, but the components it is shaped into are generally discrete, and subject to further assembly.

What are the 7 steps of manufacturing

It's not an easy trip, but these eight steps help make it possible:Develop the Product Vision. The product vision is the seed the finished goods will grow from.Research the Vision.Design the Product.Finalize the Design.Test the Prototype.Manufacture the Product.Get Feedback and Do More Testing.Official Release.

What are the 3 phases of the manufacturing process

This process consists of three major stages: the pre-processing stage, the processing stage and the post-processing stage.

What are the 7 types of processes

Isothermal process.Adiabatic process.Isoehoric process.Isobasic process.Reversible process.Irreversible process.Cyclic process.

What are 3 examples of manufacturing industries

Examples of manufacturing include automotive companies, bakeries, shoemakers and tailors, as they all create products, rather than providing services.

What are three examples of processes

First, a few examples of processes: Cleaning the store. Finding an email address. Deploying software.

What are the 5 basic functions in manufacturing

For a firm engaged in making discrete products, the functions are :Processing.Assembly.Material handling and storage.lnspection and test.Control.

What are the 3 P’s of manufacturing

What is 3P Method 3P stands for Production, Preparation, and Process. It is a lean manufacturing method that helps businesses to assess and improve their production processes. The goal of 3P is to streamline production, eliminate waste through product, and increase efficiency.

What are the 3 major components of manufacturing a product

The three general categories of costs included in manufacturing processes are direct materials, direct labor, and overhead. Note that there are a few exceptions, since some service industries do not have direct material costs, and some automated manufacturing companies do not have direct labor costs.

How many different processes are there in manufacturing

In this article, we'll explore the five types of manufacturing processes, where you'll learn all about what a manufacturing process is and which is the best for your business. But be sure to read on to the end, as we have a sixth bonus manufacturing process you can use instead.

What are the 3 basic types of processes or methods for production

Types of production processes: Mass Production. Batch Production. Job Production.

What are the three main categories of manufacture

Three common types of manufacturing production processes are: make to stock (MTS), make to order (MTO), and make to assemble (MTA). Such strategies have advantages and disadvantages in labor costs, inventory control, overhead, customization, and the speed of production and filling orders.

What are the three major manufacturing methods

These three manufacturing types work as follows:Make-To-Stock (MTS) In this system a factory produces goods that are held in stock at stores and showrooms.Make-To-Order (MTO) The make to order method allows the manufacturer to wait until orders are received before production begins.Make-To-Assemble (MTA)

What are the 3 main production processes

Types of production processes: Mass Production. Batch Production. Job Production.

What are the three manufacturing processes

There are three types of manufacturing production process; make to stock (MTS), make to order (MTO) and make to assemble (MTA).

What are the three types of manufacturing process

When we're talking about the three types of manufacturing we're ultimately referring to, make to stock manufacturing (MTS), make to order manufacturing (MTO), and make to assemble manufacturing (MTA). These three types of manufacturing are rather common among manufacturers.

What are the three 3 types of production process

There are three common types of basic production systems: the batch system, the continuous system, and the project system. In the batch system, general-purpose equipment and methods are used to produce small quantities of output (goods or services) with specifications that vary greatly from one batch to the next.

What is 3S in manufacturing

A 3S (Shine) Audit is essential for creating a safe and orderly workspace in the manufacturing industry. 3S stands for Sort, Set in Order, and Shine, which refers to the three steps of organizing your work area.

What are the types of processes

Isothermal process.Adiabatic process.Isoehoric process.Isobasic process.Reversible process.Irreversible process.Cyclic process.

What are the three 3 major components of the manufacturing system

A manufacturing system must have three basic components:Inputs – raw materials or parts that will be used in the manufacturing process.Processes – the methods and techniques used to transform the inputs into the desired output.Outputs – the products or services that are created as a result of the manufacturing process.

What are the 3 main means of production

The elements needed to produce goods and services: land, labour, and capital.

What are the 3 factors of production called

An entrepreneur is a person who combines the other factors of production – land, labor, and capital – to earn a profit.