What is the process of 3D printing

What Is 3D Printing Three-dimensional (3D) printing is an additive manufacturing process that creates a physical object from a digital design. The process works by laying down thin layers of material in the form of liquid or powdered plastic, metal or cement, and then fusing the layers together.

What is a process called 3D printing or additive manufacturing

In simplest terms, additive manufacturing is 3D printing. This emerging manufacturing practice allows researchers to create physical, three-dimensional objects directly from a computer design file.

What are 3D prints called

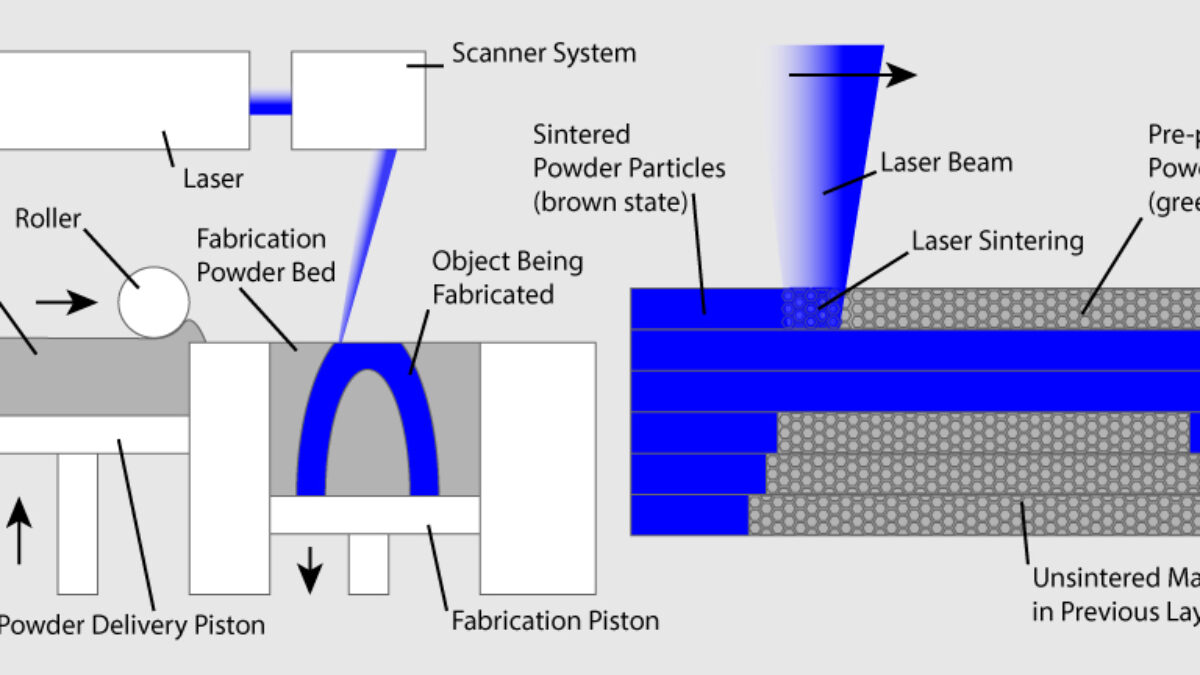

There are several types of 3D printing, which include: Stereolithography (SLA) Selective Laser Sintering (SLS) Fused Deposition Modeling (FDM)

Why is 3D printing called printing

The term "3D printing" originally referred to a process that deposits a binder material onto a powder bed with inkjet printer heads layer by layer.

What is the process of 3D Modelling

A 3D model is essentially made up of vertices, which come together to form a mesh and act as the core of the 3D model. Each point on the model can be manipulated to change the shape. By using coordinate data, the software identifies the location of each vertical and horizontal point, all relative to a reference point.

Is 3D printing a long process

This can vary from as little as 30 minutes to several days. The bigger the part and the greater the complexity, the longer it takes to print. However, a simpler and smaller item can be printed much faster.

What is the process of 3D printing drugs

Utilising a layer-by-layer production process, 3D printing can produce printlets (3D printed tablets) that are individualised to a patient's therapeutic requirements (e.g. dosage, drug combination and drug release profiles) and personal preferences (e.g. shape, size, texture and flavour)[13–16].

Is 3D printing additive or subtractive manufacturing

The differences between additive manufacturing and subtractive manufacturing are significant. Additive manufacturing, often referred to as 3D printing, adds successive layers of material to create an object. Subtractive manufacturing removes material to create an object.

What is 3D printing known for

What Can 3D Printers Make Designers use 3D printers to quickly create product models and prototypes, but they're increasingly being used to make final products, as well. Among the items made with 3D printers are shoe designs, furniture, wax castings for making jewelry, tools, tripods, gift and novelty items, and toys.

What type of printing is 3D printing

What is 3D Printing 3D printing or additive manufacturing (AM) technologies create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until physical part is created.

What is 3D printing and why is it useful

3D printing allows for the design and print of more complex designs than traditional manufacturing processes. More traditional processes have design restrictions which no longer apply with the use of 3D printing.

What is the design process in 3D design

3D Design. The design process involves designing projects based on plans, ideas, documentation, sketches, and drawings. It involves the visualization of a model and turning ideas into three-dimensional structures.

What is the most common 3D printing process

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers.

How long does a 3D printing process take

This can vary from as little as 30 minutes to several days. The bigger the part and the greater the complexity, the longer it takes to print. However, a simpler and smaller item can be printed much faster.

What is the process of 3D pen

Like their 3D printer counterparts, 3D pens utilize heat to extrude malleable plastic to form various shapes. Most 3D printing pens have a filament feeding slot, a heated tip, a button or squeezing area to command the extrusion process and a power input (or built-in battery).

What are the 4 steps of 3D printing

Generally speaking, to print a model through 3D printing needs to go through the following four steps: modeling, slicing, printing, and post-processing.

Is 3D printing considered manufacturing

3D printing, also known as additive manufacturing, has come a long way since it was first developed in the 1980s. While 3D printing originated as a tool for rapid prototyping, it has now evolved to cover a number of different technologies.

Is additive manufacturing a process

Additive manufacturing (AM) or additive layer manufacturing (ALM) is the industrial production name for 3D printing, a computer controlled process that creates three dimensional objects by depositing materials, usually in layers.

What 3D printing is most used

The most common 3D printing method that uses plastic material is fused deposition modeling (FDM). In FDM 3D printing, thermoplastic filaments are melted and shaped one layer at a time.

What is 3D technology

In computing, a 3D image is a computer-generated graphic that provides the perception of depth similar to a real-world object. This technology is commonly used in movies, video games, graphics and virtual reality (VR) projects like the metaverse.

What is the process of 3D printing plastic

Plastic 3D Printing Processes

Stereolithography (SLA) 3D printers use a laser to cure thermosetting liquid resins into hardened plastic in a process called photopolymerization. Selective laser sintering (SLS) 3D printers use a high-powered laser to fuse small particles of thermoplastic powder.

Is 3D printing a technology

Digital fabrication technology, also referred to as 3D printing or additive manufacturing, creates physical objects from a geometrical representation by successive addition of materials. 3D printing technology is a fast-emerging technology. Nowadays, 3D Printing is widely used in the world.

Why is 3D printing so popular

3D printing has become popular so quickly because it makes manufacturing accessible to more people than ever before. This is partly due to the price (the starting price for a basic 3D printer is about $300), but also the small size of the printers compared to traditional manufacturing.

Why is 3D printing good for the world

Reduced Environmental Impact

This reduces the need for virgin resources and helps to reduce the amount of waste sent to landfills. As a result, 3D printing is helping to reduce the environmental impact of manufacturing. In addition, 3D printing is also helping to reduce the cost of manufacturing.

What is the process of design called

Design thinking is a non-linear, iterative process that teams use to understand users, challenge assumptions, redefine problems and create innovative solutions to prototype and test. Involving five phases—Empathize, Define, Ideate, Prototype and Test—it is most useful to tackle problems that are ill-defined or unknown.