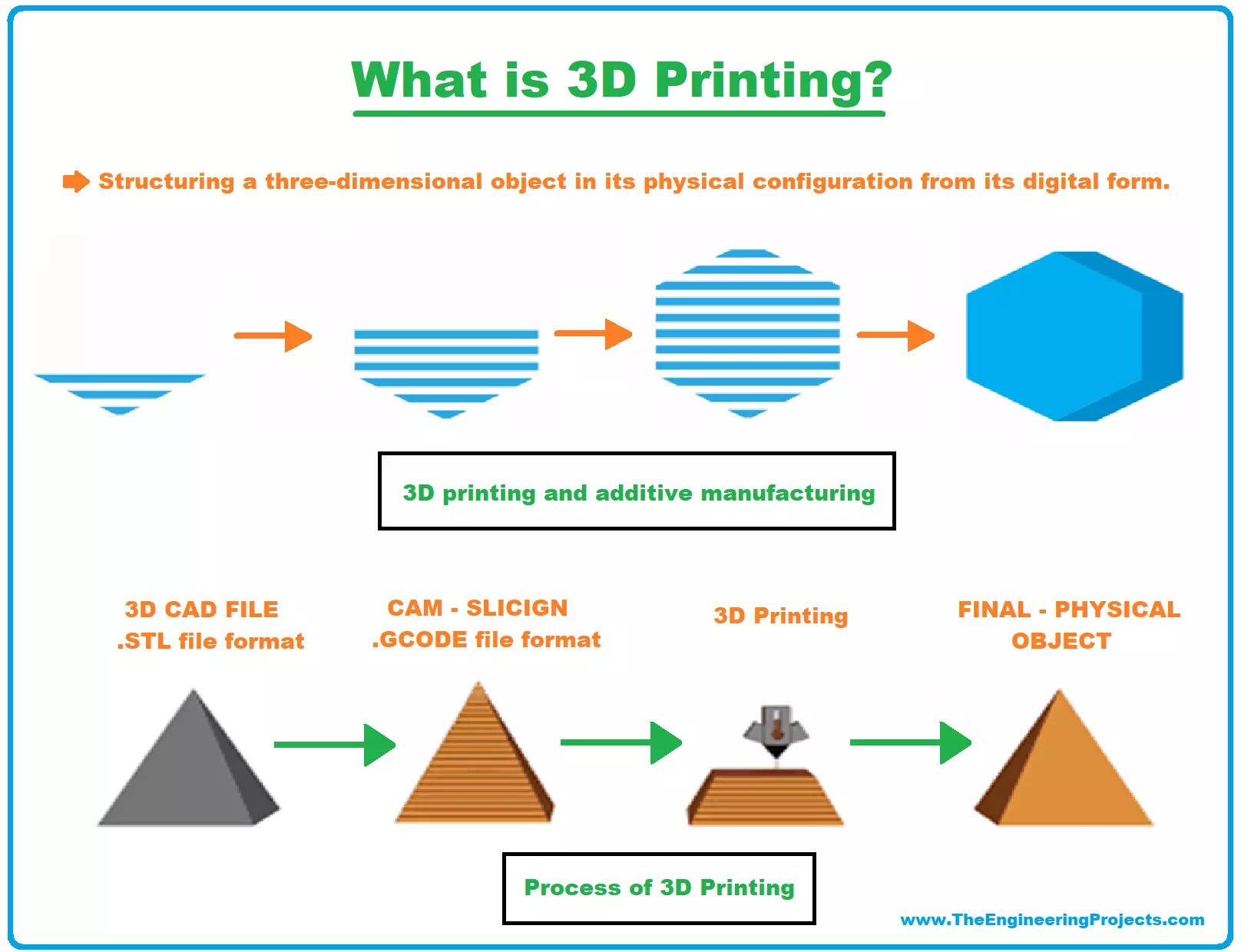

What is 3D printing also known as

3D printing (also known as additive manufacturing) is a process that creates 3-dimensional physical objects from a digital model. 3D printers are machines that specialize in additive manufacturing i.e. they build parts by adding layers of material in successive layers.

What is the process of 3D printing

What Is 3D Printing Three-dimensional (3D) printing is an additive manufacturing process that creates a physical object from a digital design. The process works by laying down thin layers of material in the form of liquid or powdered plastic, metal or cement, and then fusing the layers together.

What was the first 3D printing process called

The first process where three-dimensional material is deposited to form an object was done with material jetting or as it was originally called particle deposition.

What is another name for 3D printing in construction

Alternative terms for this process include "additive construction." "3D Concrete" refers to concrete extrusion technologies whereas Autonomous Robotic Construction System (ARCS), large-scale additive manufacturing (LSAM), or freeform construction (FC) refer to other sub-groups.

What is 3D printing known for

What Can 3D Printers Make Designers use 3D printers to quickly create product models and prototypes, but they're increasingly being used to make final products, as well. Among the items made with 3D printers are shoe designs, furniture, wax castings for making jewelry, tools, tripods, gift and novelty items, and toys.

What type of printing is 3D printing

What is 3D Printing 3D printing or additive manufacturing (AM) technologies create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until physical part is created.

Why is it called 3D printing

3D printing is a process in which a digital model is turned into a tangible, solid, three-dimensional object, usually by laying down many successive, thin layers of a material.

What is the process of 3D Modelling

A 3D model is essentially made up of vertices, which come together to form a mesh and act as the core of the 3D model. Each point on the model can be manipulated to change the shape. By using coordinate data, the software identifies the location of each vertical and horizontal point, all relative to a reference point.

Which of the following processes does 3D printing use

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

Which 3D printing process is the most popular 3D printing process

Fused Deposition Modeling

Extrusion (also known as FDM for Fused Deposition Modeling or FFF for Fused Filament Fabrication) is the most common 3D printing technique.

What are the 4 types of 3D printing

Lots of 3D printers use PBF technology. The most common types of printers are selective laser sintering ( SLS), direct metal laser sintering (DMLS), selective laser melting (SLM), HP's Multi Jet Fusion ( MJF), high-speed sintering (HSS) and electron beam melting (EBM).

What are the two types of 3D printing

Two main 3D printing methods, Fused Deposition Modeling (FDM) and Stereolithography (SLA), are popular in the industry because of their unique capabilities. If you want to choose the best 3D printing technology, understanding the differences between FDM and SLA is important.

What type of 3D printing is most common

Fused deposition modeling (FDM)

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used type of 3D printing at the consumer level.

What is the process of 3D printing plastic

Plastic 3D Printing Processes

Stereolithography (SLA) 3D printers use a laser to cure thermosetting liquid resins into hardened plastic in a process called photopolymerization. Selective laser sintering (SLS) 3D printers use a high-powered laser to fuse small particles of thermoplastic powder.

Why is it called 3D

Definition. 3D (three-dimensional) shapes are solid shapes that have three dimensions including length, depth and width. These are shapes that occupy space. This means that we can touch and feel them.

What is the design process in 3D design

3D Design. The design process involves designing projects based on plans, ideas, documentation, sketches, and drawings. It involves the visualization of a model and turning ideas into three-dimensional structures.

What are the three types of 3D modeling

There are three major types of 3D modeling that fall under the rubric of CAD software: solid modeling, wireframe modeling, and surface modeling. These three types are further divided into subtypes based on specific features.

What is the most common 3D printing process

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers.

What is the most common process used by 3D printers

Moreover, plastic material for 3D printing is cost-effective compared to other materials. The most common 3D printing method that uses plastic material is fused deposition modeling (FDM). In FDM 3D printing, thermoplastic filaments are melted and shaped one layer at a time.

What are the 3 main types of 3D printing

The three most established types of 3D printers for plastics parts are stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM).

What are the 3 main type of 3D printing

There are several types of 3D printing, which include: Stereolithography (SLA) Selective Laser Sintering (SLS) Fused Deposition Modeling (FDM)

What are the 2 main types of 3D printers

Fused deposition modeling (FDM) and stereolithography (SLA) are the two most popular types of 3D printers on the market. Both 3D printing technologies have been adapted and refined for the desktop, making them more affordable, easier to use, and more capable.

What are three methods of 3D printing

There are several types of 3D printing, which include: Stereolithography (SLA) Selective Laser Sintering (SLS) Fused Deposition Modeling (FDM)

What is the process of filament making

The process of creating 3D printing filament is called "compounding." First, raw plastic resin in the form of pellets is produced. These pellets can be mixed with additives to obtain desired mechanical properties. The mixture is then dried, extruded to the desired width (usually 1.75 or 2.85 mm), and wound on a spool.

What is another word for 3D

What is another word for 3D

| three-dimensional | lifelike |

|---|---|

| realistic | living |

| natural | naturalist |

| naturalistic | near |

| photo-realistic | believable |